PCBA packaging method: Anti-static bag + Anti-static bubble wrap +

Good quality carton box

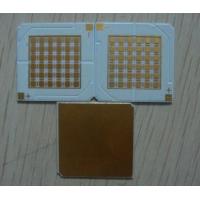

Product Description

Product area: military products

Product structure: 18 layers HDI third-order, FR-4, TG170, inner and outer copper

thickness 35um, hole copper 20um, impedance ±10%, plate thickness 3.20mm,

Immersion gold 2u", SMT + plug-in + post-welding

Printed circuit board (pcb) and PCBA products

Communication terminal, communication station, electronic

communication, optical fiber, optical module, communication

equipment, communication instrument, computer, household appliance,

testing equipment, testing instrument, instrument, SD card, SG

card, mobile phone, computer, various antennas, cars, music

Equipment, playback equipment, banking equipment, medical

instruments, medical equipment, medical equipment, aerospace,

aviation, military, LED, OLED, OLCD power control power supply,

industrial power supply, communication power supply, automotive

power supply, office equipment, digital

products,computers,etc.Applications;

Flexible circuit board (FPC) and FPCA product areas

CD, hard disk, printer, fax machine, scanner, sensor, mobile phone,

connector, module, walkie-talkie antenna card, high-end camera,

digital camera, laser head, CD, medical, instrumentation, drive,

automotive instrumentation, medical instrument, Medical equipment,

banking equipment, industrial instruments, LED light bars,

military, aviation, aerospace, defense and other high-tech

products, of which more than 70% of the products are exported to

Europe, America, Europe, Central Europe, Western Europe, Southeast

Asia, Asia-Pacific and other countries and area.

PCB Assembly services

SMT Assembly

Automatic Pick & Place

Component Placement as Small as 0201

Fine Pitch QEP - BGA

Automatic Optical Inspectio

Through-hole Assembly

Wave Soldering

Hand Assembly and Soldering

Material Sourcing

IC pre-programming / Burning on-line

Function testing as requested

Aging test for LED and Power boards

Complete unit assembly (which including plastics, metal box, Coil,

cable assembly etc)

Packing design

Conformal coating

Both dip-coating and vertical spray coating is available.

Protecting non-conductive dielectric layer that is

applied onto the printed circuit board assembly to protect the

electronic assembly from damage due to

contamination, salt spray, moisture, fungus, dust and corrosion

caused by harsh or extreme environments.

When coated, it is clearly visible as a clear and shiny material.

Complete box build

Complete 'Box Build' solutions including materials management of

all components, electromechanical parts,

plastics, casings and print & packaging material

Testing Methods

AOI Testing

Checks for solder paste

Checks for components down to 0201"

Checks for missing components, offset, incorrect parts, polarity

X-Ray Inspection

X-Ray provides high-resolution inspection of:

BGAs

Bare boards

In-Circuit Testing

In-Circuit Testing is commonly used in conjunction with AOI

minimizing functional defects caused by

component problems.

Power-up Test

Advanced Function Test

Flash Device Programming

Functional testing

Quality Processes:

1. IQC: Incoming Quality Control (Incoming Materials Inspection)

2. First Article Inspection (FAI) for every process

3. IPQC: In Process Quality Control

4. QC: 100% Test & Inspection

5. QA: Quality Assurance based on QC inspection again

6. Workmanship: IPC-A-610, ESD

7. Quality Management based on CQC, ISO9001:2008, ISO/TS16949

Design file format:

1. Gerber RS-274X, 274D, Eagle and AutoCAD's DXF, DWG

2. BOM (bill of materials)

3. Pick and place file (XYRS)

Advantages

1. Turnkey manufacturing or quick-turn prototypes

2. Board-level assembly or complete system integration

3. Low-volume or mixed-technology assembly for PCBA

4. Even consignment production

5. Supoorted capabilities

PCB, FPC process production capability

| Technical ltem | MassProduct | Advanced Technology |

| 2016 | 2017 | 2018 |

| Max.Layer Count | 26L | 36L | 80L |

| Through-hole plate | 2~45L | 2~60L | 2~80L |

| Max.PCBSize(in) | 24*52" | 25*62" | 25*78.75" |

| The layer number of FPC | 1~36L | 1~50L | 1~60L |

| Max.PCBSize(in) | 9.8"*196" | 9.8"*196" | 10"*196"Reel to reel |

| Layeredplatelayer | 2~12L | 2~18L | 2~26L |

| Max.PCBSize(in) | 9"*48" | 9"*52" | 9"*62" |

| Combination of hard and soft layers | 3~26L | 3~30L | 3~50L |

| Interconnect HDI | 5+X+5Interconnect HDI | 7+X+7Interconnect HDI | 8+X+8,Interconnect HDI |

| HDI PCB | 4~45L | 4~60L | 4~80L |

| Interconnect HDI | 3+20+3 | 4+X+4Interconnect HDI | 4+X+4,Interconnect HDI |

| Max.PCBSize(in) | 24"*43" | 24"*49" | 25"*52" |

| Material | FR-4 Rogers | FR-4 Rogers | FR-4 Rogers |

| Base material | Halogenfree,LowDK | Halogenfree,LowDK | Halogenfree,LowDK |

| Build-up Material | FR-4 | FR-4 | FR-4 |

| BOard,Thickness(mm) | Min.12L(mm) | 0.43 | 0.42~8.0mm | 0.38~10.0mm |

| Min.16L(mm) | 0.53 | 1.60~8.0mm | 0.45~10.0mm |

| Min.18L(mm) | 0.63 | 2.0~8.0 | 0.51~10.0mm |

| Min.52L(mm) | 0.8 | 2.50~8.0mm | 0.65~10.0mm |

| MAX(mm) | 3.5 | 10.0mm | 10.0mm |

| Min.CoreThickness um(mil) | 254"(10.0) | 254"(10.0) | 0.10~254(10.0mm) |

| Min.Build up Dielectric | 38(1.5) | 32(1.3) | 25(1.0) |

| BaseCopperWeight | Inner Layer | 4/1-8 OZ | 4/1-15 OZ | 4/1-0.30mm |

| Out Layer | 4/1-10 OZ | 4/1-15 OZ | 4/1-30 OZ |

| Gold thick | 1~40u" | 1~60u" | 1~120u" |

| Nithick | 76~127u" | 76~200u" | 1~250u" |

| Min.HOle/Land um(mil) | 150/300(6/12) | 100/200(4/8) | 100/200(4/8) |

|

| Min.Laser via/landum(mil) | 60/170(2.4/6.8) | 50/150(2/6) | 50/150(2/6) |

|

| Min. IVH,Hole size/landum(mil) | 150/300(6/12) | 100/200(4/8) | 100/200(4/8) |

|

| DieletricThickness | 38(1.5) | 32(1.3) | 32(1.3) |

| 125(5) | 125(5) | 125(5) |

| SKipvia | Yes | Yes | Yes |

|

| viaoNhie(laserviaon BuriedPTH) | Yes | Yes | Yes |

|

| Laser Hole Filling | Yes | Yes | Yes |

|

| Technicalltem | Mass Product | Advanced Technolgy |

| 2017year | 2018year | 2019year |

| Drill hole depth ratio | ThroughHole | 2017year | .40:1 | .40:1 |

| Aspet Ratio | Micro Via | .35:1 | 1.2:1 | 1.2:1 |

| Copper Filling Dimple Size um(Mil) | 10(0.4) | 10(0.4) | 10(0.4) |

| Min.LineWidth&space | lnner Layer um(mil) | 45/45(1.8/1.8) | 38/38(1.5/1.5) | 38/38(1.5/1.5) |

| Plated Layer um(mil) | 45/45(1.8/1.8) | 38/38(1.5/1.5) | 38/38(1.5/1.5) |

| BGAPitch mm(Mil) | 0.3 | 0.3 | 0.3 |

| Min.PTH Hole ring um(mil) | 75(3mil) | 62.5(2.5mil) | 62.5(2.5mil) |

| Line Width Control | ∠2.5MIL | ±0.50 | ±0.50 | ±0.50 |

| 2.5Mil≤L/W∠4mil | ±0.50 | ±0.50 | ±0.50 |

| ≦3mil | ±0.60 | ±0.60 | ±0.60 |

| Laminated structure | Layer by layer | 3+N+3 | 4+N+4 | 5+N+5 |

| Sequential Build-up | 20L Any Layer | 36L Any Layer | 52L Any Layer |

| Multi-layer overlay | N+N | N+N | N+N |

| N+X+N | N+X+N | N+X+N |

| sequential Lamination | 2+(N+X+N)+2 | 2+(N+X+N)+2 | 2+(N+X+N)+2 |

| Soft and hard bonding | 2+(N+X+N)+2 | 2+(N+X+N)+2 | 2+(N+X+N)+2 |

| PTH filling process | PTH resin plug hole + plating fill

Electroplated hole/copper plug hole | PTH resin plug hole + plating fill

Electroplated hole/copper plug hole | PTH resin plug hole + plating fill

Electroplated hole/copper plug hole |

|

|